Case IH AF11: What You Need To Know

Proclaiming 2024 the “Year of the Combine” Case IH hosted an exclusive preview in Orlando, Florida, to showcase its newest grain harvesting technology: the AF 11 combine.

The sleek, muscular model will be available for pre-order from Case IH dealers later this summer – albeit in a limited production run – before a full rollout for crop year 2025. Case claims it is the largest harvester of its kind available in North America.

Customer driven product development – customers sought a similar look and feel to its popular Steiger, Magnum, and Puma tractor lines – was a driving force along AF11’s development curve. Pricing details for the new machine will be made available later this summer through the dealer network, according to Case IH executives.

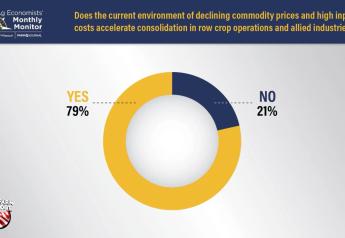

As the farm consolidation trend continues (again, Case listened to its customer base here and they overwhelmingly believe it will, according to the company), and equipment buyers prioritize performance metrics and tech integrations over pure paint color, Case is pushing all its chips to the center of the table.

“We’re reemerging as the leader in harvesting supremacy with this clean, simple and best-in-class design,” said Kurt Coffey, vice president – North America, also noting the machine’s dual rotor design and ability to harvest 8,000 bushels of corn per hour.

Coffey, a Central Illinois farm kid, spent this past summer entrenched alongside the design team as well as riding alongside test farmers in the U.S. and Western Canada.

“Harvesting corn at 7 mph – this thing just kept eating,” he added. “What you see here today in this AF11 combine represents real-world problem solving with a purposeful design. This isn’t a beauty pageant.”

Leo Bose, harvesting segment leader, says the release of AF11 represents for him a major career milestone, and for Case IH’s customers it portends the future of harvesting.

“We focused on three key areas: capacity, technology, and run time,” Bose said. “Our harvesting technology will help farmers save grain and harvest faster, with more quality grain going into that tank. And our farmers overwhelmingly told us: we have to have (more) run time.”

AF11: What You Need to Know

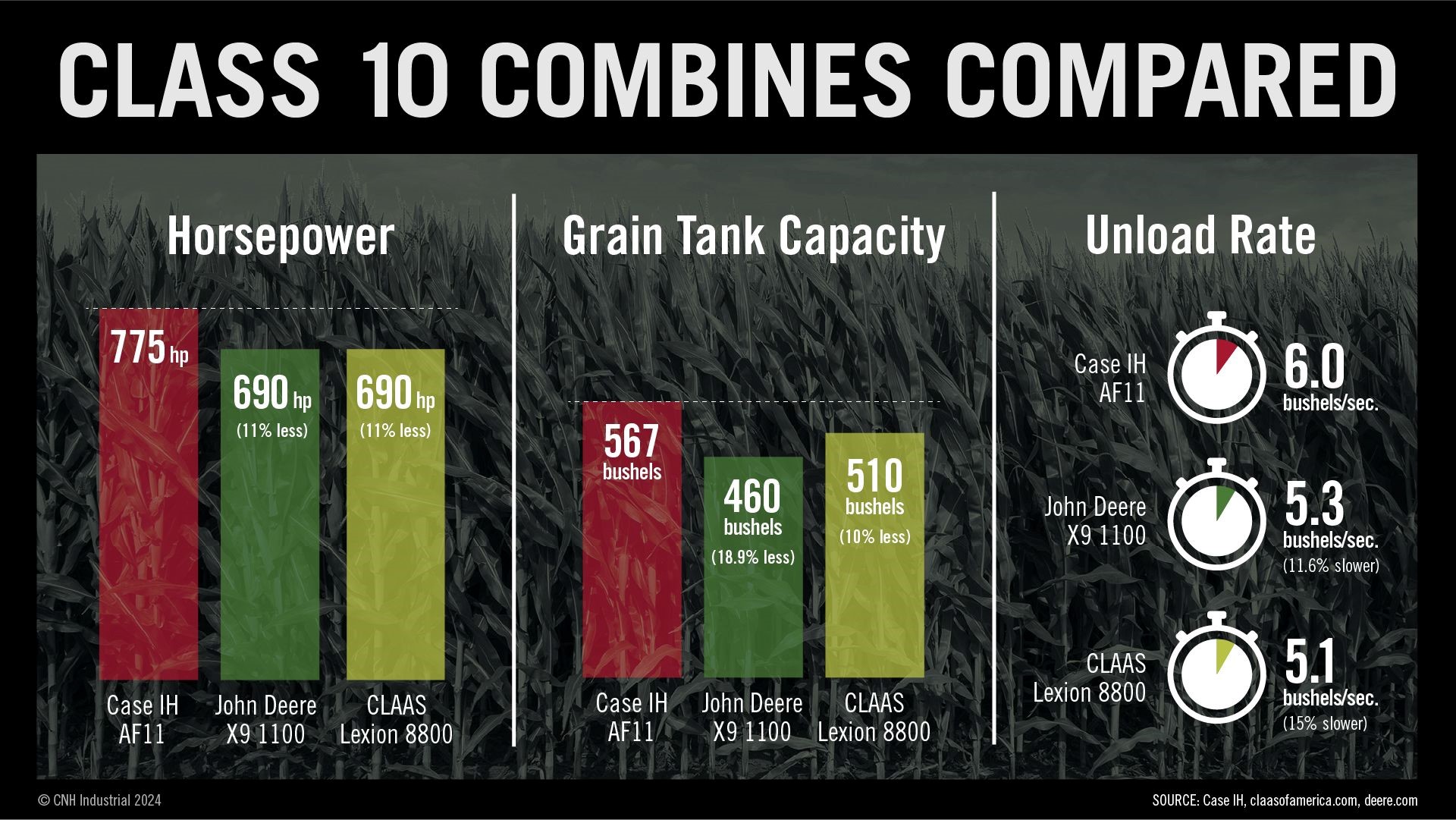

- Class 10+: The Association of Equipment Manufacturers (AEM) benchmarks combines up to Class 10, with the top end of that classification topping out at 680 HP. Case is slugging AF11 as a “Class 10+” – a class that currently does not exist on the scale – because it puts out 775 HP of grain chopping power.

- Higher capacity: Case IH test farmers who ran the AF11 this summer realized its larger grain tank (567 bushels) and wide configuration allows operations to potentially downsize their harvesting fleets while still covering the same amount of ground. Its 50-foot draper head or 16-row corn chopper – which eventually will be available in even wider configurations – also enable higher capacity and more harvesting per hour.

- Tech and Automation: AFS Harvest Command comes fully integrated off the factory line, and a radar-controlled residue spreader at the rear ensures grain stubble is evenly distributed. Inside the spacious cab, dual mounted Pro 1200 displays provide operator visibility and data visualization. The new AFXL2 dual rotor represents a step forward for the company in what its calling a "dynamically optimized cleaning and separating system", and automated grain leveling keeps harvested grain level when traversing uneven ground.

- Runtime: Farmers will notice improvements here via AF11’s 6 bushel per second offload rate, unlocking more operating hours in an already time crunched process. Also of note is a new drivetrain configuration (horizontally mounted at the rear of the combine) that distributes weight and torque for more efficient drivetrain operation and fuel savings. And the entire power plant is set into the machine in a way that makes it easier for techs to access components for preventative maintenance or DIY service.

Saskatoon, Canada, canola and cereal grains farmer Jason LeBlanc ground tested the AF11 this summer on his 1,600-acre operation.

“It will help us cut down on hired labor, the capacity in this machine is something we’re really excited about,” he said. “The capacity, the grain unloading time, harvesting the same amount with less fuel burned per acre – it’s a massive deal for an operation like ours.”

Of course, there is more to know about this new machine than we can fit into this article, so head over to caseih.com/en-us/unitedstates/products/harvesting/af-series to explore further.

You can also catch the new combine in person as its unveiled to the greater public for the first time at the upcoming National Farm Machinery Show in Louisville, Kentucky.