6 Concept Technologies To Watch In 2024 And Beyond

Being on the early edge of the product development curve has its benefits and its drawbacks.

For one, concept technologies can be exhibited with the caveat that what you’re seeing today is not the products’ final form. Opportunities to refine and tinker and improve before full commercialization remain.

On the other side of the coin, most farmers are less inclined to devote brainpower to tech that is five, ten, sometimes even 20 years down the pipeline. Show me what can help my farm today versus what might help my farm in two decades.

Yet, we believe there is intrinsic value in foresight.

If farmers stay apprised of technological advancements and envision how they’ll be applied to crop production in the years ahead, they can plan now for the future.

Here are six technology and machinery concepts that show potential to improve efficiency and sustainability:

Bondioli & Pavesi Electronic Data Interchange (EDI) PTO driveshaft

A farmer cannot manage what cannot be measured. Enter German-outfit Bondioli & Pavesis’ concept PTO driveshaft.

The concept “smart” component logs and displays performance data from the implement PTO drive system to the controller in the cab. It sends predictive maintenance alerts into the tractor cab so that the operator is aware of any potential maintenance or performance issues.

Its embedded sensors stream real-time data on torque, speed, axial force as well as vibrations, and it monitors the degree of overlap of the two PTO shaft halves. Productivity is optimized and machine upkeep costs and downtime are reduced, according to the company. The EDI PTO shaft was future-proofed, so it will be able to interface with both today’s conventional and the coming wave of driverless tractor platforms.

As of this writing, the EDI PTO driveshaft is not yet available for purchase in the U.S.

New Holland – CR Twin Axial Rotor Combine Harvester

New Holland – CR Twin Axial Rotor Combine Harvester

Developed in response to transportation regulations around the globe, this new harvesting implement features a unique drivetrain mounted horizontally. This innovative design enables maximum power density while keeping the implements’ footprint within generally accepted road transport widths.

It also features a centrally mounted implement gearbox, enabling a considerable increase in the width of the chassis and threshing channel. The wider threshing channel dramatically increases harvesting capabilities, according to New Holland, meaning users can expect to efficiently harvest just under 2,500 acres in one season with the new combine.

Pesky in-field blockages are cleared via automated forward-reverse thrusting, and the patented cleaning system is optimized for more efficient grain load out by a network of pressure sensor and cameras that measure and automatically adjust parameters for optimal output.

The implement is available today. New Holland advises those interested to contact your dealer for more information.

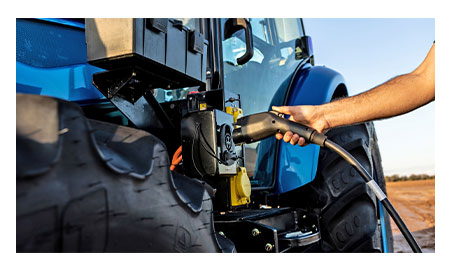

New Holland – T4 Electric Power Tractor

New Holland – T4 Electric Power Tractor

New Holland seems to have struck a balance between improved efficiency and operator safety with its new battery powered T4 Electric Utility tractor. The company claims it is the first electrically driven tractor with autonomous features.

Increased operator efficiency is accomplished via two common operating modes that those familiar with unmanned technologies will likely recognize. Follow-Me Mode allows the tractor operator to accomplish field tasks outside of the cab as the tractor continues operating autonomously. It also enables the tractor to follow its operator and respond to various hand gestures telling it to stop, go, turn, etc. Route Mode allows for driverless operation along predefined guidance lines (A-B lines, field boundaries, waypoints on a map, etc.), as well.

Alongside these intriguing features, the tractor’s enhanced safety features – such as 360-degree field of vision sensing via front mounted sensors, and automatic detection and coupling/uncoupling of implements at the rear PTO shaft – combine with a unique configuration that one day could prove quite useful for smaller tasks around the farm.

New Holland says that units are available now and to reach out to your New Holland dealer for more information.

Nexat – Holistic Crop Production System

Nexat – Holistic Crop Production System

Nexat stands for Next Generation Agriculture Technology, and the German startup has brought to life its own intriguing vision for the future of farm machinery.

Holistic Crop Production System is a diesel powered, electrically driven wide-span carrier vehicle with swappable implements that can perform field tasks with onboard modular attachments. Implements can be switched out in under 10 minutes by a single operator.

Nexat has built and sold between 18 and 20 carrier vehicles this year, according to Hannah Ovelheey, marketing manager.

“We have machines running in Ukraine, Romania, Germany, United States and Brazil,” she shared, noting increasing interest from farmers in Eastern Europe and Canada.

As with most ag innovations of late, it’s all reliant on a sophisticated network of advanced sensors feeding real time data into AI/ML algorithms. Autonomous operation is in the offing, but for now, a uniquely positioned operator cab offers 320-degrees of protected oversight.

“This machine is built to work 24-hours, so compared to a person working 8-hours, you have quite high throughput,” Ovelheey added.

Saphir - GrindStar implement

Saphir - GrindStar implement

This new implement is the result of a joint development project among three German equipment manufacturing peers. The collective collaborated on a design that creates optimum field conditions for the germination of volunteer cereals, cover crop seeds or a subsequent intercropping in the first post-harvest pass.

Passively rotating rotors till soils ultra-flat, resulting in a uniform dispersion of tilled fine earth. Enhanced separation of soil from stubble (residue) as well as further processing of field residues creates ideal conditions for residue decomposition.

This process can occur at speeds of up to 11 mph, thus the operator is able to cover more ground while consuming less fuel. And its power requirements are comparable to that of a common harrow, yet GrindStar achieves similar output to that of a more powerful pull-behind mulching implement. As a result, the collective claims post-harvest residue processing is sped up and increased germination rates are achieved, with less groundwater and fossil fuel needed compared to field cultivation with conventional discing implements.

As of this writing GrindStar is not available commercially in the U.S.

Steyr/Case IH – Hybrid CVT Tractor

Steyr/Case IH – Hybrid CVT Tractor

This hybrid diesel-electric concept tractor was developed to reduce Co2 emissions as well as offer an energy efficient alternative.

A 260-hp rated diesel engine is fitted in a redesigned front end alongside two integrated electric motors. The diesel engine powers an on-board generator that transfers power to the electric motors. Electricity is then converted to mechanical energy and rerouted back through the front axle differential. Onboard “superconductors” bank extra generated energy until it is ready to be released.

Braking energy recovery systems also capture and transfer power to the tractor’s power distribution system, like Tesla’s regenerative braking technology in automobiles. Other noteworthy features include electric steering and an “E-Eco” drive mode that enables diesel-to-electric driving at low speeds.

The Hybrid CVT Tractor is still in prototype phase and is not available for purchase yet.

Editor's Note

Clinton Griffiths, AgDay host and Farm Journal editor, gathered information on the above technologies while attending Agritechnica 2023 back in November. He joined 400,000-plus attendees from around the globe at the biannual event in Hanover, Germany. Read more of Clinton's on-the-ground coverage from Agritechnica here.