Spoiled Grain? There Are Apps for That

Grain bin monitoring technology adoption is driven primarily by profitability, grain quality, and farmer safety.

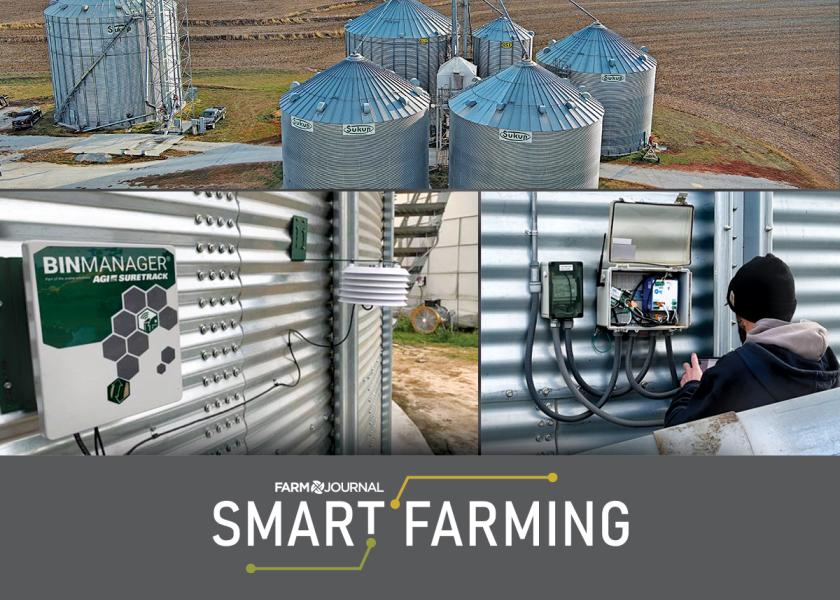

“Farmers have monitored their grain bins for many years – they would open the bin, smell it, and check the level by banging a wrench against the side,” says David Postill, senior VP of digital and global marketing, Ag Growth International (AGI). “Today we have much better, safer and accurate methods.”

AGI’s BinManager is one notable grain bin monitoring system, but most operate within a similar framework: in-bin sensors, or cables, record data. Farmers set their target moisture percentages (often 14% to 15% for corn, higher for soybeans) and the technology goes to work in the background. Push notification alerts flag any issues.

“The bin is the farmer’s bank account. Imagine if you had to take your yearly salary and bury it in the backyard, wait a year, and then dig it up and take it to the bank,” Postill says. “You would never do that. You’d safeguard it, monitor it, and maybe even put it into a higher-yielding account.”

Boots-on-the-ground perspective

Ulysses, Nebraska, farmer Lukas Fricke knows firsthand the value of technology. He farms with his brother on ground his father and grandfather worked for decades.

Union Farms, the brothers’ farming operation, holds both corn and soybeans across an array of bin sizes. They truck grain to the local elevator, and they truck beans to crush into soybean oil to feed their hogs. The duo stuck a toe in the water a couple years ago, adding AGI monitoring tech to one of the soybean bins.

“The return-on-investment was fast – it paid for itself that first year,” says Fricke, adding the automation unlocked 300-400 extra bushels of soybean moisture.

The brothers were sold.

“We just did the other three bins this year – now every piece of grain on our farm is being managed and watched and guarded,” he says.

Fricke cautions farmers might suffer sticker shock at the up-front costs – the brothers went for the top tier AGI monitoring suite, after all – but it proved a wise investment.

“During harvest we’ve got pig loads going out and coming in, feed coming in, fields to harvest, manure to put away, if you don’t have your head screwed on it can get out of hand very quickly,” Fricke says.

Breaking down the basics

The basic conditions being monitored are temperature and moisture levels (relative humidity). Integrated on-farm weather stations, as well as Co2 monitoring sensors, represent a higher level of management. The goal, according to HTS Ag President Adam Gittins, is perfectly conditioned grain with zero farmer entry.

“I like to joke there are two types of farmers out there: those that have had some grain spoil, and those that lie about it,” Gittins says.

While mold, generally the product of low temperature and high moisture, is the main nemesis, the systems prevent over drying, too. Water is weight, and weight is money at the elevator.

“The sky is the limit when it comes to what it can do,” says Gittins, noting data aggregation with planter and combine data for full traceability from field to elevator remain the next big breakthroughs.

HTS Ag installs and services OPI Grain Management Systems, which Gittins says has 40 years of grain monitoring experience. He says the OPI Blue system gives farmers remote access to real time moisture, temperature, and CO2, as well as automation, set to the grower’s parameters and using bin specific weather conditions. “This fall, we had a run of cool moist air run at my bin site, and I was able to rehydrate my beans a few points with OPI’s fan automation," says Gittins.

“With most tech being cloud based, you can have true up and downstream data integration and track grain through the last mile,” he adds. “It’s an exciting time to be a part of this technology.”

Boosting quality of life

Matt Koch, chief marketing officer, Sukup, echoes that sentiment. Koch spent his early days as a developer and engineer in automation systems. Today he’s putting that background to work helping farmers understand how Sukup’s monitoring technology can improve quality of life.

Sukup recently closed on a Des Moines, Iowa, based custom automation company, Ramco Innovations, to build out its yet-to-be-released bin monitoring ecosystem. Details are scant, but what Koch can confirm is the finished product will hit the market in 2025. And it will make users’ lives easier.

“If we can sell back quality of life to our customers, that is really where we’re going to win,” Koch says. “Bins are a commoditized product – but if I told you we can automate the process today that you’re doing manually, and you can have full visibility into the process and not have to be there in person, that’s how we can sell back quality of life.”