Science Boosts Soybean Yields For Nebraska Farmer

Wading into a dark green soybean sea in early August, Jimmy Frederick smiled and kept his nerve, pretending all he wanted was to push past the century mark. Behind the grin, Frederick hung his hopes on heavy plants hiding beneath a bursting canopy: The field was screaming out 150-plus bushels per acre.

On Oct. 27, 2017, Frederick harvested 163.9 bu. per acre across 40 acres of an irrigated 130-acre field. The remainder of the field averaged more than 100 bu. per acre. With a focus on seed population, spacing and biologicals, Frederick attributes the fall bounty to spring effort. He says the booming yields were established when the planter rolled.

Frederick, 36, farms 2,500 acres of corn and soybeans across a mix of terraces, hills and bottom ground alongside his father, James, in southeast Nebraska, near Rulo. Typically, Frederick’s soybean yields bounce from 80 bu. to 90 bu. per acre on irrigated ground and 70 bu. to 80 bu. per acre on nonirrigated ground. The record 130-acre field, with a gumbo-type soil, soared in 2014 with 96 bu. per acre.

In 2016, Frederick used a 160,000 plant population across his soybean acreage, but in 2017, he dropped it to 145,000, intending to increase lateral branching off the stem and curb the need for the plants to steal from neighbors. On the 130 irrigated acres, he went even lower, dipping to a 115,000 plant population. It was a dollars-for-dollars trade.

“I wanted to cut seed costs and use the money elsewhere to improve yield. I was excited because the money I saved paid for my in-furrow fertilizer and biologicals,” he says.

Getting a bit of a late start due to weather, Frederick punched ground on May 20, planting into 30" rows. He keeps the specific variety tight to his chest but says it was a dicamba-

tolerant soybean (2.8 maturity group).

“Population was extremely important for Jimmy,” says Chris Masters, CEO of Biovante. “The lower plant population allowed greater expression of the genetics, and that can add 3 bu. to 4 bu. by itself.”

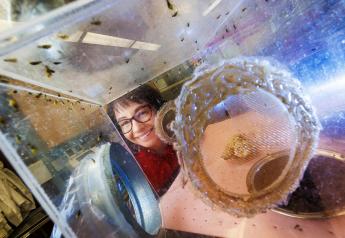

Frederick believes the initial yield key was delivery of biologicals coupled with highly effective machinery. “Everything was right at planting. I used a Precision Planting FurrowJet to put down biologicals in-furrow and out the wings. It was the perfect combination for germination,” he says.

Masters is a proponent of singulation in soybeans and says Frederick’s soybeans are a prime example of potential benefits.

“If you aim for 1" or 1.5" spacing, you’re letting the plants express themselves genetically,” Masters says. “Crowd the space, and we see minimized lateral branching. You’ll get closer internodes, increased lateral branching and more flowers when you mix the right equipment with the right biologicals.”

At season’s end, three products made the biggest yield impact, according to Frederick: BioCore, BioMate and Elixor.

BioCore is a talc-based seed treatment enhanced with micronutrients and microorganisms. BioMate is a four-sugar food source that features two strands of bacteria, which feed soil microorganisms and provide energy to the plant. Elixor (pH-neutral), though not a biological, is a systemic fungicide and bactericide intended to boost immunity and preserve beneficial soil microbes around the seed.

“I spent an extra $2.05 to $2.10 per bushel. Those are not crazy costs, but that’s a lot when you don’t know the outcome at the end of a season,” Frederick says. “But I was excited early on because the laterals shot out, and there was an unusual amount of blooms after flowering. I knew we had something special.”

Nights in the low 70s, 2" of water each week, low weed pressure and consistent sunshine were significant parts of the yield puzzle. Frederick also stayed on top of the crop and played no waiting games.

“I walked it all the time and tissue-sampled,” he says. “Bugs were smoked right away. When the beans needed something, I didn’t hesitate.”

Producer Cory Snethen grows corn and soybeans near Frederick in Richardson County. He says Frederick’s 130-acre field is not particularly great ground and attributes the big yield entirely to management: “That dirt isn’t the best in the world, but those beans were incredible. I’ve never seen so many pods.

“Jimmy is very aggressive on finding stuff that pays,” Snethen continues. “Everybody wants to sell us something, but Jimmy does a great job of actually sorting through and finding return on investment. He’ll tell you straight when he’s wasting his time, and he’ll tell you when you can get money back in your pocket.”

Frederick’s season-long efforts paid off in October. He rolled into the field and began cutting, stunned by yield monitor numbers that surpassed his highest estimates.

“I’m sitting there cutting, just blown away by the flashing numbers that were as special as the beans looked,” he says.

His only regret? Bushels left in the field. Frederick’s 163.9-bu. mark was even more impressive considering lost bushels. Big, woody stems acted like “another set of ratchet bars” Frederick says, and they ground some of the soybeans to powder. Frederick thinks double-digit yield numbers slipped away in phantom loss.

“We drove as slow as possible, had the concave wide open, and it made no difference,” Frederick says. “Behind the combine you could see bean hulls all over the ground that didn’t make it to the bin, but I’m learning for next year.”

Frederick plans to extend biological use and in-furrow treatments across all acres in 2018: “I’m going to lower my passes, change around product rates and learn how to do better.”

This year, Masters intends to steer Frederick toward even lower plant populations. “I’m going to push for Jimmy to go even lower than 115,000—maybe even less than 100,000. We’re going to try new things and compare in-furrow versus no in-furrow.”

What is Frederick’s takeaway from success in 2017? Science works, he says. “Every move counts, and I’ve got so much to learn. The coolest thing is watching science in action in my field and letting the plant act like the genetics intend by tapping into everything from spacing to germination.”

The longer Frederick talks about end-of-season yields, the more he points backward in time to the crucial aspects of planting. He insists his yield numbers began climbing when his planter rolled on May 20.

“I had the right equipment with the right biologicals. Sure, they work good separately, but put them together, and you’ve got bread and butter,” Frederick says.