Manage Input Costs by Understanding Soil Type

Imagine you have four daughters, it’s nearly Christmas and you still need to buy presents, explains Erich Eller, owner of Forefront Ag Solutions. One daughter sees a sweater she loves and eureka, you hit the jackpot and buy four of them in her size. Come Christmas day, one daughter is ecstatic, one is OK with the gift, one complains it’s the wrong size and the fourth says she just hates everything about it.

Blanket gifting doesn’t usually go over well. Neither does blanket fertilizer application.

Just like the four daughters have different personalities and tastes, so does your soil. It’s important to treat each soil type differently to maximize productivity.

More bang for the buck

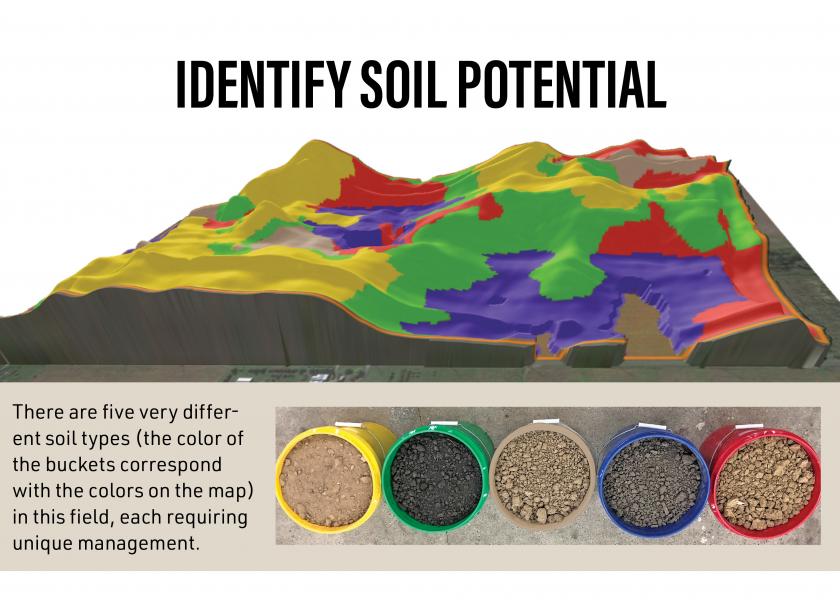

One of the first steps Eller takes to evaluate a field is to run a Veris machine. The machine uses sensors that detect changes in soil types to create a 3-D map of the field, which can then be used for prescription input applications.

“We bring that info into our software and combine it with historical data, imagery and harvest data,” Eller says. “Then we see the different soil types and use data to define yield goals, broken out by these soil zones, which drives fertility and seeding decisions.”

Making adjustments based on soil type might save money on fertilizer, or at least allow you to get the most bang for your buck.

“If we have five soil types, why do we put out a flat rate of nitrogen?” Eller adds. “You’re leaving top-end yield on the table and overfeeding the under performers.”

On the highest producing

soil types, Eller sees the highest nitrogen efficiency.

”I’ve been able to pull 0.5 lb. per bushel of corn while lower performing soils can take 1.5 lb. to produce 1 bu.,” he explains.

The same goes with seeding rates. Generally speaking, higher yield potential justifies somewhat higher seeding rates for corn, and the opposite is also true. In soybeans, higher seeding rates are best in low-performing areas while a lower seeding rate in high-potential areas provide more pods per plant.

Because it takes 100 years, according to Purdue University research, to create 1" of topsoil, you don’t need to take soil tests with sensor tools every year. Eller asks his farmer customers to test every field once using sensor technology, at $10 per acre — unless there’s been major dirt work or flooding.

3 Steps to Become a Precision Farmer

To help make the most of technology, some of which you might already have on your farm, Erich Eller, with Forefront Ag Solutions, suggests the following:

- Map soils. Beyond sending soil samples off to a lab, work with someone who has sensor technology to create detailed maps, which are as accurate as it gets.

- Use clean data. Work with someone who understands how to incorporate foundational info and clean up past data.

- Implement your findings. Even if you don’t currently have the precision application equipment, collect the data anyway. When you upgrade down the road, you’ll have the data ready to roll, Eller says.